But without 5G performance assurance, will operators be able to make the most of the opportunity?

Private 5G networks appeal to the largest manufacturers for factories and industrial automation where they can control security and architecture. In order to capture their rightful share, mobile operators will need to focus on the ‘mobility’ use cases in Industry IoT, design service wraps with security and performance guarantees, and work with partners.

Internet of Things (IoT) is often associated with exciting consumer innovations like smart home, connected cars, smart retail, or wearables.But industry in general will experience a dramatic disruption with the improvements brought by 5G mobile connectivity. ABI Research expects digital factory revenues to hit $375 Billion USD in 2030 up from $59 Billion USD today. Machine tools, asset tracking, and connected programmable logic controllers will experience the most growth in terms of connected service revenue over the next ten years.

Industrial Internet of Things, also known as IIoT, is a major pillar of Industry 4.0, the fourth industrial revolution where factories are increasingly automated, benefiting from full connectivity and the ability to connect anything from anywhere easily. 5G offers high capacity, wireless flexibility and low-latency performance, and is the natural choice to support the evolution to the industrial digital future.

Beyond cutting the cables, what can 5G do for Industry?

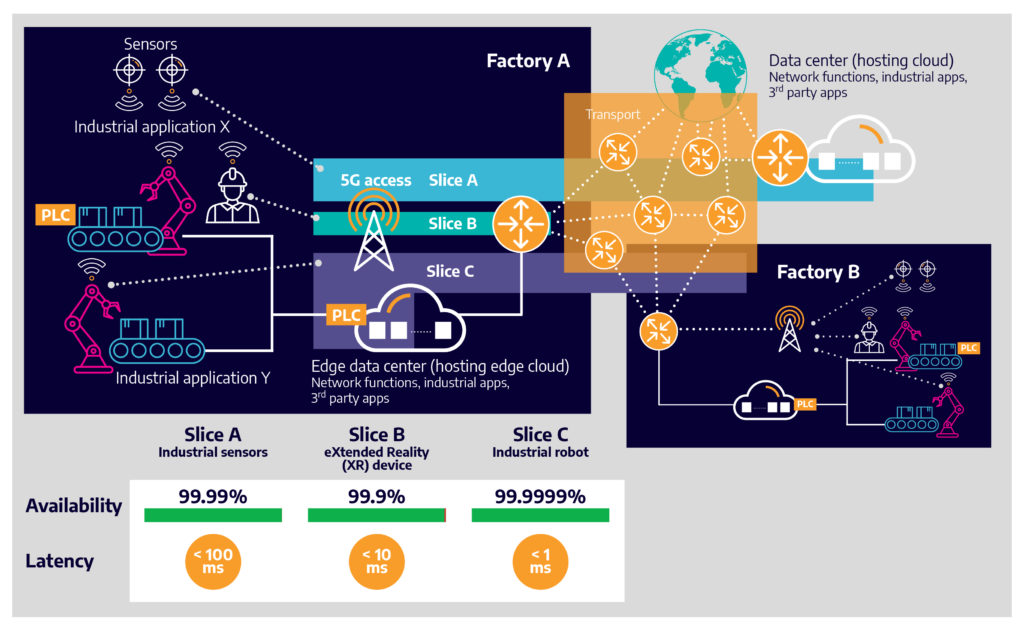

Industrial IoT covers a wide range of use cases with different requirements but in general, they are a combination of Massive IoT, Critical IoT and Broadband IoT. In manufacturing, 5G can be used to track and process data from sensors that monitor each of the products at any stage of the production or delivery process (Massive IoT). Industrial robots can benefit from ultra-reliable low latency and high availability (Critical IoT). Security cameras or augmented reality devices for workers benefit from the high capacity offered by 5G (Broadband IoT).

Other industrial IoT examples can be found in mines, agriculture and container ports, where asset tracking, reliable robotic control, and automated surveillance can only be achieved by using 5G.

5G offers high capacity, wireless ubiquity and flexibility combined with low-latency performance. It is the natural choice to “cut the cables”, which makes it easier to adapt the physical locations of operations, avoid unreliable WiFi and get rid of the many different IoT connectivity standards used today, such as LoRa. 5G also offers increased reliability and the ability to offer network slices for different types of use cases with specified availability and latency guarantees. These network slices can be dynamically created or modified as needed.

Mobile operators have a substantial opportunity if they focus on the right use cases and partnerships

Industrial IoT can be a big opportunity for network operators because of the huge and diverse market potential. A recent 5G for business: a 2030 market compass report found that 47% of the total ICT market (up to $700 billion) enabled by 5G could be served by network operators by 2030.

But it could also be a challenge for operators to remain relevant because 5G offers the possibility for enterprises to create their own private networks with unlicensed spectrum. German electronics manufacturer Bosch recently applied for private 5G licenses, saying 5G private campus local area networks are the way forward, control security and architecture.

In addition, 5G opens up the market to numerous industry players that will compete and or partner with operators for 5G solutions for enterprise customers. In order to partner and/or compete with these new players, operators will need to change their current mindset and improve channel on-boarding and billing systems to support different partner types and to monetize different service levels for 5G applications.

Mobile operators will have the opportunity to monetize different offers based on Quality of Service (QoS) required by each type of 5G service or application. For Industrial IoT which is business-critical, this will be of extreme importance. The ultra-low latency and high availability required by an industrial robot will require a more stringent service level agreement (SLA) than a set of sensors than only need basic connectivity.

What are the challenges of meeting performance requirements for 5G Industrial IoT?

It will be important that mobile network operators can measure and manage diverse 5G service performance requirements by having tighter control of quality and being able to prove that the required service guarantees for all of the services are met. Operators will need to take on more responsibility to ensure that latency, reliability and connectivity are provided on a continuous 24/7 basis to prevent any degradation.

But collecting performance data is not just an end in itself. This data needs to be processed and digested so any anomaly or degradation can be detected and fixed before it impacts service quality. This becomes more important with 5G where the volume and complexity of data requires highly automated processes.

Industry 4.0 is creating millions of new endpoints that need to be interconnected. However, the existing performance management systems can’t support it, which is creating an opportunity for new experts and providers to step in.

Accedian’s Skylight has the flexibility to measure performance from the underlying physical network infrastructure and extend it to each of the different 5G network slices. Performance measurements can be automated and orchestrated to adapt to the specific requirements of the industrial application requirements. Skylight also provides visibility across different vendors and technologies through a single pane of glass. We call this Skylight performance analytics – it provides the means to visualize service availability and performance in real time and also the insights needed to act when necessary. Skylight analytics also facilitates the reporting of SLAs associated with the different levels of services offered by the operator.

Stay tuned for more blogs in our 5G Use Cases and Performance Management blog series!

Improved delivery, better visibility: How Accedian and VMware are working together to help CSPs navigate the 5G world

Improved delivery, better visibility: How Accedian and VMware are working together to help CSPs navigate the 5G world

Adding a new dimension of visibility to the Cisco Full-Stack Observability portfolio with Accedian Skylight

Adding a new dimension of visibility to the Cisco Full-Stack Observability portfolio with Accedian Skylight